CNC Turning

Our CNC turning service capabilities

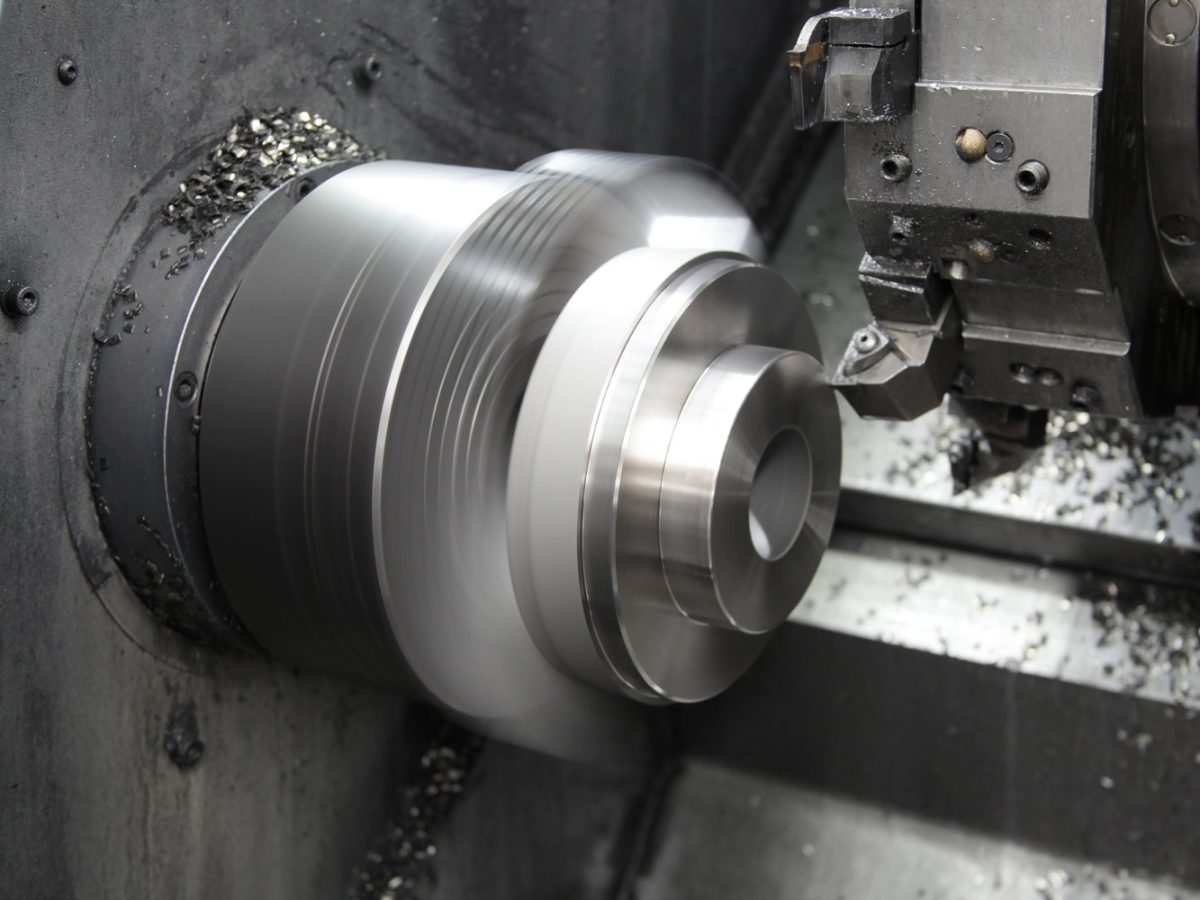

CNC lathe

From prototyping to full production runs. CNC lathes will allow you to produce highly accurate, high quality parts to meet even your most stringent requirements.

CNC turning machines are able to provide low cost parts for simple cylindrical geometries. Live tooling is available for more complex geometries and is assessed on a case by case basis.

Maximum capabilities for CNC turning

| Part size limitations | Metric units | Imperial units |

| Maximum part diameter | 431 mm | 17 in |

| Maximum part length | 990 mm | 39 in |

| Maximum swing over the carriage | 350 mm | 13.7 in |

| Maximum spindle through-hole | 40 mm | 1.5 in |

Maximum speed: 1700RPM

Motor power: 640W

Available materials for CNC machining

Here is a list of our standard CNC machining materials available

| Plastics | Aluminum | Stainless steel | Other steels | Other metal |

| ABS | 6061-T6 | 303 | Mild steel 1018 | Brass C360 |

| Nylon 6 | 6082 | 304 | Mild steel 1045 | Copper C101 |

| POM (Delrin) | 7075 | 316 | Mild steel A36 | Copper C110 |

| Polycarbonate | 5083 | 2205 Duplex | Alloy steel 4140 | Titanium Grade 2 |

| PVC | 17-4 | Alloy steel 4340 | ||

| HDPE | 420 | Tool steel O1 | ||

| PTFE (Teflon) | Tool Steel A2 | |||

| PEEK | Tool Steel D2 | |||

| G-10 | Tool Steel S7 |

Tolerances

The table below summarizes the standard tolerances of the parts produced by Creative Product Solutions. Tolerances up to .0008” (0.020mm) are available upon request.

| Part size / Dimension | Tolerance | Angularity |

| < 12’’ (300 mm) | ± .005’’ (0.125 mm) | ± 0.5° |

| < 24’’ (600 mm) | ± .010’’ (0.250 mm) | ± 1.0° |

| < 36’’ (900 mm) | ± 1/64’’ (0.400 mm) | ± 1.0° |

CNC turning design guidelines

The table below summarizes the recommended and technically feasible values for the most common features encountered in CNC machined parts.

| Feature | Recommended size | Feasible size |

| Min. feature size | Ø 2.5 mm | Ø 0.50 mm |

| Internal edges | R 8 mm | R 0.25 mm |

| Minimum wall thickness | 0.8 mm (for metals) 1.5 mm (for plastics) | 0.5 mm (for metals) 1.0 mm (for plastics) |

| Holes | Diameter:standard drill bit sizes Depth: 4 x diameter | Diameter: Ø 0.5 Depth: 10 x diameter |

| Threads | Size: M6 or larger Length: 3 x diameter | Size: M2 |

Quality assurance

- Inspection report included in every order. Full dimensional inspection reports on request

- Material certifications and test reports available on request

- Batch inspection in concurrence with ISO2859

- Strict NDA agreement

- Performance tracking on lead time and quality

Upload files and configure parts to get a quote

Disclaimer

Tuff Cor (Pty) Ltd will be able to help you with all your manufacturing and product development need through our in-house services and knowledge. We make use of our large network of reliable supplier for any service we do not have in-house.

F.A.Q

What is CNC turning services

What is a CNC turner

What is the difference between machining and turning

Machining can be done with various cutting tools, including drills, milling cutters, and lathe tools. Turning can only be done with lathe tools.