Resin Casting

Most commonly a thermosetting resin is used that polymerizes by mixing with a curing agent (polymerization catalyst) at room temperature and normal pressure. The resins are named by analogy with plant resins, but are synthetic monomers for making polymer plastics. The so-called synthetic resins used include polystyrene resin, polyurethane resin, epoxy resin, unsaturated polyester resin, acrylic resin and silicone resin.

Epoxy resin has a lower viscosity than polyurethane resin;, polyester resin also shrinks markedly while curing. Acrylic Resin in particular the methyl methacrylate type of synthetic resin, produces acrylic glass (also called PMMA, Lucite, Plexiglass), which is not a glass but a plastic polymer that is transparent, and very hard. It is suitable for embedding objects (such as, for example, acrylic trophies), for display purposes. Styrene is a similar liquid monomer at room temperature, which will also polymerize into clear glass-like polysryrene plastic, with addition of a suitable catalyst.

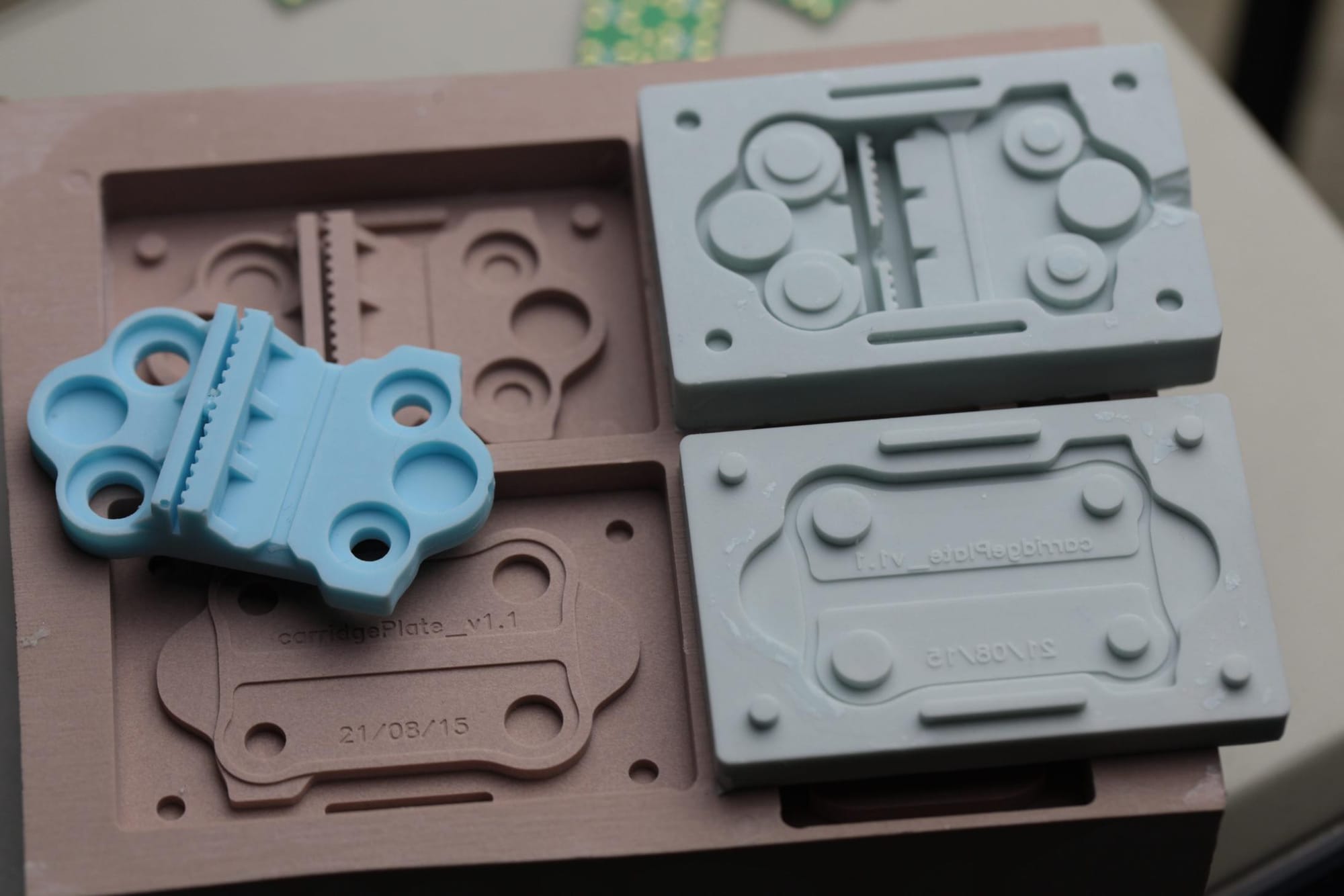

A flexible mold can be made of latex rubber, room temperature vulcanized silicone rubber or other similar materials at relatively low cost, but can only be used for a limited number of castings.

The simplest method is gravity casting where the resin is poured into the mold and pulled down into all the parts by gravity. When the two part resin is mixed air bubbles tend to be introduced into the liquid which can be removed in a vacuum chamber. The casting can also be done in a vacuum chamber (when using open molds) to either extract these bubbles, or in a pressure pot, to reduce their size to the point where they aren't visible. Pressure and/or centrifugal force can be used to help push the liquid resin into all details of the mold. The mold can also be vibrated to expel bubbles.

Each unit requires some amount of hands-on labor, making the final cost per unit produced fairly high. This is in contrast to injection molding where the initial cost of creating the metal mold is higher, but the mold can be used to produce a much higher number of units, resulting in a lower cost per unit.

Vacuum and Pressure Chambers

Pressure Systems (pressure chambers and compressors) offer the optimal method for creating molds and resin castings that are truly bubble free.

Vacuum Systems (vacuum chambers and vacuum pumps that pull 29 inches of mercury) are used to remove the air from high viscosity materials like silicone rubber before pouring. They are also ideal for vacuum degassing liquid plastics for making bubble free castings.

Electronics Potting

In electronics, potting is a process of filling a complete electronic assembly with a solid or gelatinous compound for resistance to shock and vibration, and for exclusion of moisture and corrosive agents. Thermosetting plastics or silicone rubber gels are often used, though epoxy resins are also very common.

Disclaimer

Tuff Cor (Pty) Ltd will be able to help you with all your manufacturing and product development need through our in-house services and knowledge. We make use of our large network of reliable supplier for any service we do not have in-house.

Contact

- 57 Genl Van Reyneveld Street, Persequor, Pretoria, South Africa

Contact

- 57 Genl Van Reyneveld Street, Persequor, Pretoria, South Africa